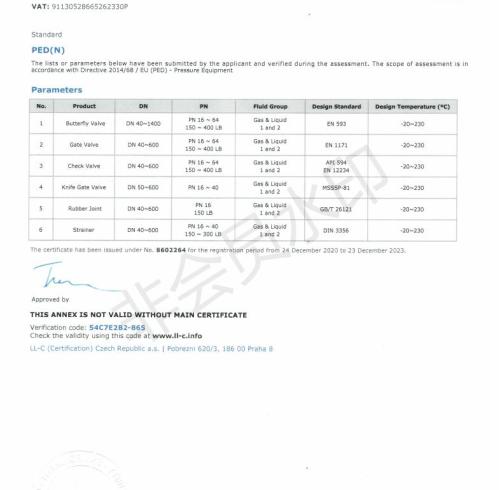

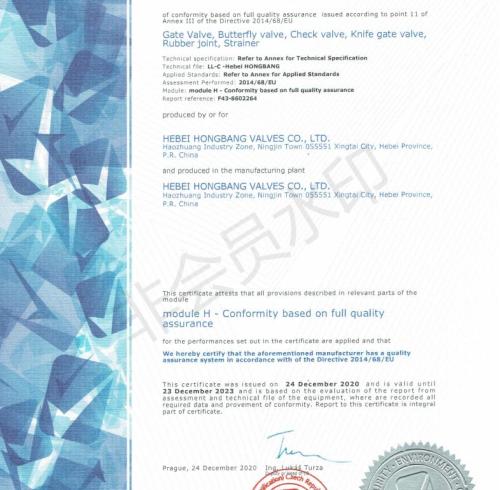

PED was adopted on May 29, 1997, and took effect on November 29, 1999. There is a 30-month grace period before May 28, 2002, that is, products can choose to apply PED or the original regulations of each country (but those applicable to the original regulations of each country can only be circulated in that country). From May 29, 2002, the original regulations of various countries will be abolished, and PED becomes the compulsory regulation of pressure equipment in Europe.PED Certification Full name: Pressure Equipment (PED) certification. PED is a compulsory regulation issued by the member states of the European Union on the safety of pressure equipment.The difference betweenIf a simple comparison is made with ASME certification, PED certification is the safety certification of specified products, while ASME certification is the factory certification of specified standards. This is the biggest difference in nature between the two. It is worth paying attention to that in PED certification, the basic safety requirements stipulated by the directive are enforced, but the technical standards of the products are not. Unless specified by the user, the manufacturer is free to choose any technical standard. This point and domestic provisions: must be mandatory implementation of national standards, ministerial standards or industry standards is also very different.PEDThe Pressure Equipment Directive PED 2014/68/EU is a directive. All equipment with design pressure over 0.5bar, regardless of its pressure and volume, must comply with PED regulations. Equipment such as fire extinguishers, pressure gauges, valves, safety valves, air tanks, tower tanks, pipes, fittings, steam equipment, etc. for loading or conveying fluids must comply with PED regulations.Pressure equipment and assemblies with a maximum pressure above 0.5 bar."Pressure equipment" means vessels, pipes, safety parts and pressure parts.PED is applicable to European Economic Area EEA countries, namely EU 15 countries (Austria, Belgium, Denmark, Germany, Greece, Spain, France, Ireland, Italy, Luxembourg, Netherlands, Portugal, Finland, Sweden, UK), Plus the members of the European Free Trade Agreement (Iceland, Liechtenstein, Norway).Pressure equipment and components above a specific pressure/volume threshold must:l With securityl Meets basic safety requirements for design, manufacture, and testingl Meet appropriate compliance assessment proceduresl Attach the CE mark and the mark of the relevant regulationsPressure equipment and components below a specific pressure/volume threshold must:l With securityl Design and manufacture according to sound engineering practicel Label with relevant regulations (CE mark may not be attached)All pressure equipment in the PED category must meet the basic safety requirements mandatory:(1) Design: All factors related to the intended use must be considered in the design of pressure equipment to ensure the safety of pressure equipment throughout its expected life. The corresponding safety factors must be incorporated in a comprehensive approach, and sufficient safety margins must be considered for all relevant failure modes.Requirements are provided for the design and calculation of sufficient strength, ensuring safe handling and operation, inspection methods, discharge and venting methods, corrosion and other chemical erosion, wear, charging and discharging, protection in case of exceedance of permissible limits, safety accessories and external fire.(2) Permanent connection (welding) : must be done by qualified personnel according to appropriate process procedures. For Class II, III and IV pressure equipment, procedures and personnel must be approved by the authorizing authority or a third party authorized by the Member State under Chapter 13.(3) Non-destructive testing: Non-destructive testing of permanent connections (welds) of pressure equipment must be performed by qualified personnel. For CLASS III and IV pressure equipment, the NDT personnel must be approved BY a third party accredited by the Member State under Chapter 13.(4) Final assessment; Pressure equipment must pass visual assessment and final inspection of relevant documentation. The final assessment must include a pressure test, which must meet the specified values.(5) Material: The material used to manufacture pressure equipment must be adequate for its expected life. The manufacturer must, in its technical document, state the main points of material specification in one of the following forms: 1) the use of materials in conformity with harmonised European standards; 2) Adopt pressure equipment materials approved by Europe according to Chapter 11; 3) Use specially assessed materials; For Class III and IV pressure bearing equipment, the specific assessment of materials must be carried out by an authorized authority.(6) quantitative requirements: 1) allowable stress: such as including normalizing (normalizing rolling) steel including ferritic steel (excluding fine grain steel and special heat treatment steel), shall not exceed the yield limit at 2/3 calculated temperature and the strength limit at 20℃ of 5/12; 2) Joint coefficient: 1 when all joints are confirmed to have no obvious defects by destructive test and nondestructive test of equipment; The random nondestructive test of the equipment was 0.85; 0.7 for external inspection of equipment without nondestructive testing; 3) Pressure limiting device: instantaneous pressure movement must be kept within 10% of the maximum allowable pressure; 4) Hydrostatic test pressure: shall not be less than the maximum load that may be subjected to in the bearing equipment service, considering the maximum allowable pressure and maximum allowable temperature multiplied by the corresponding coefficient 1.25 or the maximum allowable pressure multiplied by the coefficient 1.43, the maximum value of the two shall be taken; 5) Material properties: tensile test at not more than 20℃ and not more than the lowest predetermined operating temperature, the elongation after fracture is not less than 14%, and the impact failure energy of the ISO Charpy V-shaped sample is not less than 27J.Main work editor broadcast(1) Design approval; Provide the list of standard specifications used in design and manufacturing, internal standards of the enterprise, product drawings, calculations, material lists, comparative analysis of PED "basic safety requirements" compliance, hazard analysis, operation instructions, product conformance statement, etc.(2) Material approval. Provide material warranty, additional tests if necessary, supplier review of outsourced materials;(3) Welding process and welder evaluation: make evaluation plan, compile welding process specification (WPS), prepare welding test plate and welding material, and conduct process evaluation and welder evaluation test;(4) Accreditation of non-destructive testing personnel;(5) Quality system approval: provide quality manual, two annual audit reports, inconsistency items and correction records, supplementary procedure documents meeting PED requirements, etc.Selection of product classification and conformity evaluation modeManufacturers MUST ANALYZE AND categorIZE THEIR PRODUCTS TO MEET THE PED REQUIREMENTS FOR DIFFERENT PRESSURE DEVICES. Products CAN BE CLASSIFIED INTO FIVE CATEGORIES: PED CLAUSE 3.3(DESIGNED AND MANUFACTURED IN ACCORDANCE WITH THE SOUND ENGINEERING PRACTICES OF MEMBER STATES), AND FIVE CATEGORIES I TO IV. The higher the risk, the higher the classification and the stricter the rules.PED compliance assessmentThe conformity assessment procedure applies to equipment in categories I to IV.The combination of vendor choices is as followsClass I, Class II, Class III, Class IVA A1 B1+D B+DD1 B1+F B+FE1 B+E GB+C1 H1HFor products that only apply the lower requirement mode, the manufacturer may choose to apply the higher requirement mode.The modes are described as follows:A Internal production controlA1 Internal manufacturing inspection plus final review supervisionB EC type inspectionB1 EC Design checkC1 conforming typeD Production quality Assurance (ISO 9002)D1 Production Quality Assurance (ISO 9002)(Mode separate application)E Product quality Assurance (ISO 9003) final inspection and testingE1 product quality Assurance (ISO 9003)(Mode separate application)F Product InspectionG EC Individual checkH Total Quality Assurance (ISO 9001)H1 Total Quality Assurance (ISO 9001) plus special monitoring for design inspection and final assessmentMode A does not have to be verified by the notified body, whereas each other must be verified by a notified body recognized by the Member States of the European Union.Quality assurance regulations and technical regulationsPED includes provisions on quality assurance and technology. Both of them are mandatory for the manufacturer and the product. Only when both of them meet the requirements, the pressure equipment products produced can be affixed with the CE mark. In China, a number of foreign institutions can provide factory commodity insurance and technical verification services.

Nov 2,2022