Home / All / Custom Butterfly Valves / Wafer Butterfly Valves /

Custom Electric Wafer Butterfly Valve For Water Pipe

Custom Electric Wafer Butterfly Valve For Water Pipe

| Categories | Wafer Butterfly Valves |

|---|---|

| Brand | ICV Industrial Valve Manufacturer |

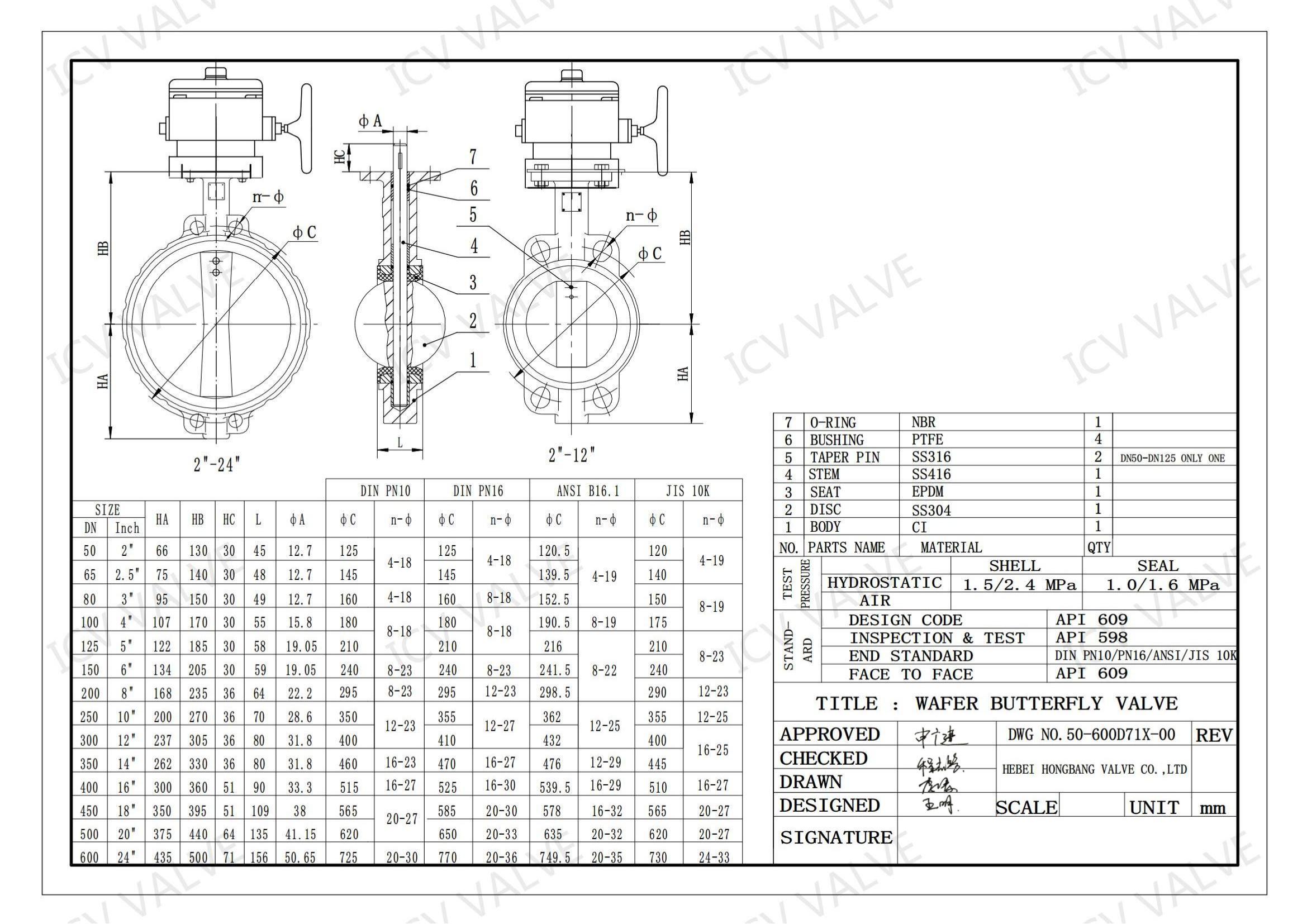

| Model | DN25-DN1600 |

| Standard | EN1092-2 PN6/10/16、AS2129 TabD/E、ASME B16.1 CL150 |

| Sample | Free |

| MOQ | 1PCS |

| Certification | ISO9001/PED/CE/EAC/TüV |

| OEM | YES |

| Color | Accept Custom |

| Certificate of origin | YES |

| 3.1 Material test | YES |

| Visit the factory | Real-time video |

| Guarantee period | 3 Years |

| FOB port | Tianjin,Qingdao,Ningbo,Shanghai |

| Terms of Payment | L/C, T/T |

| Update Time | Jul 27,2024 |

Detail Information

Custom electric wafer butterfly valve

Custom electric wafer butterfly valve is a soft sealing valve for installation with flanges

drilled in accordance with AS 2129 Table E, available in sizes 50mm through

to 300mm. The Arita butterfly valves are a high performance valve, designed

for a long service life.

Butterfly valves are fitted with the TN series quarter turn electric

actuators which are available in either a basic or smart model.

The basic model is constructed with internal mechanical cams to stop the

motor in the required position. It offers a number of standard features such

as a brushless motor, overload protection, IP67 rated housing, dome style

visual indicator, manual override, end of stroke switches, anti-condensation

heater, and a variety of voltages and wiring configurations.

Smart model is fully electronic using magnetic positioning and operates

using inbuilt firmware. In addition to the standard features, the smart

model features an OLED screen which can display position indication,

failure reports, along with menu operation and push button control to allow

numerous advanced operations such as custom positions, speed control,

local manual control, and more.

Features

▪ Ductile iron with long neck for insulation

▪ Slim disc of acid-resistant stainless steel with machined and polished edges reducing the friction between liner and disc

▪ Low operating torques allowing use of cost-effective actuators

▪ 200 μ epoxy coating up to DN 400, 250 μ polyurethane from DN 450, optionally other coatings

▪ According to PED 97/23/EC appendix 1

▪ Mounted with an electric actuator 3 x 400V/50 Hz. ON / OFF, 20 to 30 manoeuvres per day on an average. Motor duty cycle S4- 30% - 360 starts/h max. Adjustable mechanical end stops +/- 2°. Two travel limit switches for open (one) & close (one) plus two extra limit switches. Two torque switches in opening (one) & closing (one) (except OA, has no torque switch). Temperature range: Standard -20°C to +70°C. Standard protection - OA, AS, BS: IP 67 standard paint - OA, AS, BS: Epoxy 80 microns RAL 5002. Standard heater resistance (230 V). Standard cable entries - without control: 2 x M20 / with integrated controls: 3 x M20 (cable glands supply on request).

Related Products

Review

- Loading...

Please send your message to us

If you need to know more about our production standard, product catalog, sales market, product price, please fill in the form below, we have professional technicians and sales staff to serve you, we will answer any questions you have within 7 hours.

- *Name

- *Tel

- *Title

- *Content